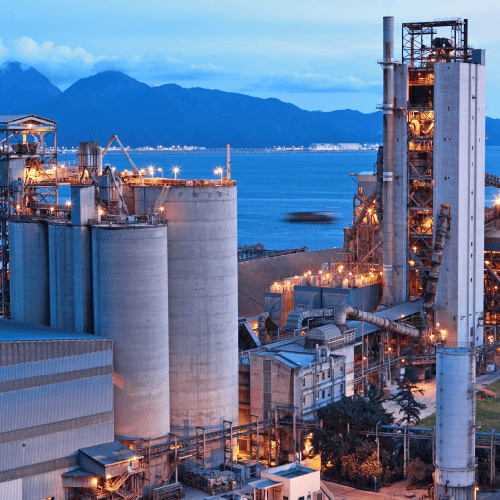

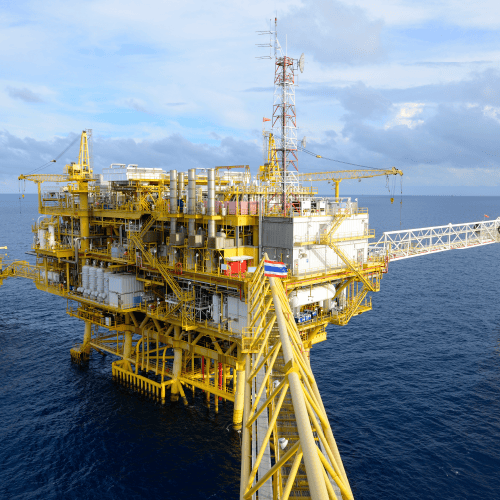

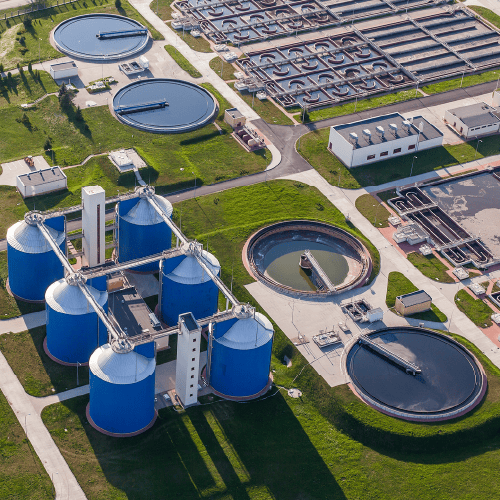

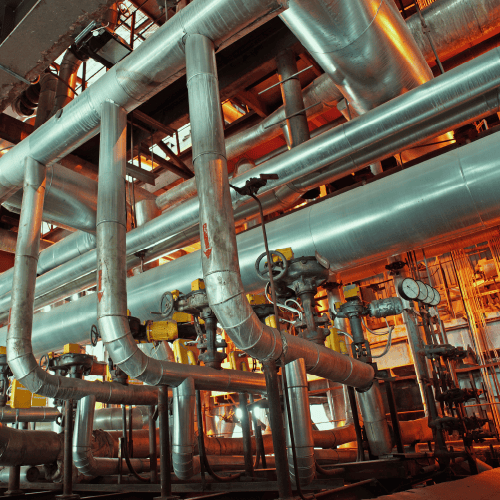

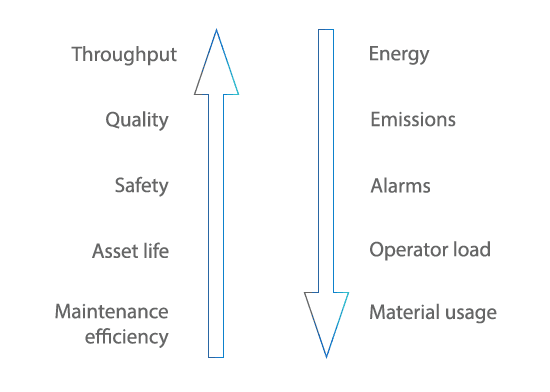

Domains of Optimisation

There are many potential factors for efficiency improvements. It is preferable to reduce some and incrase others, but usually most of them work against each other. Our complex analysis methods carried out by and experienced consultant evaluate all the possibilities. In general cases the combined dierection of movement of dominant factors ensures the business results.