Control Performance Audit

Don't be satisfied by just making it better, go for the best available

The Achievable Best Control Performance

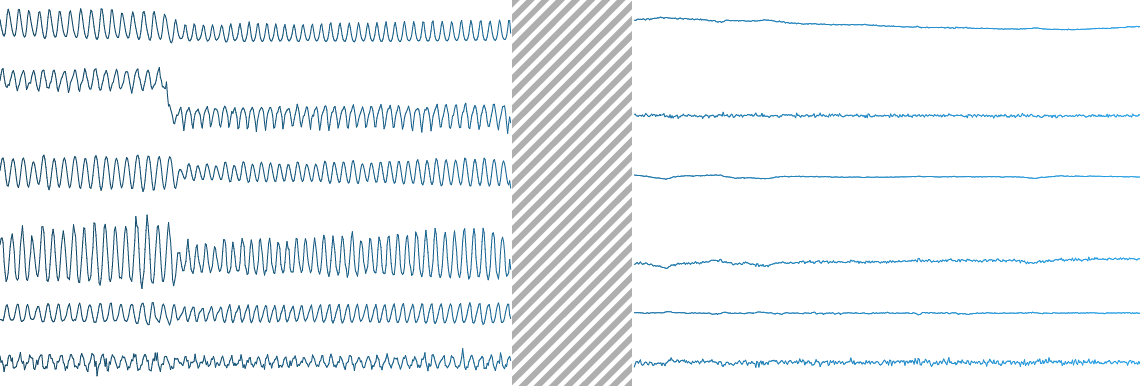

One of the primary metrics of control performance is variability. This value measures the statistical distance between the controlled and expected value. Under-performance, represented by a single number, can be measured.

The audit focuses on minimising the variability of a process cell rather than tuning individual controls for the fastest response. The dynamic response of a process cell is measured and the control behaviour is designed to make the entire process best performing. This approach moves the focus from single loop tuning to the overall performance of interactive processes like distillation columns, steam boilers or fermentation reactors.

Get the most out of your process control system

Our experience shows that complex, interactive processes often suffer from their controls under-performing. The most common symptom is a periodic oscillation on the controlled values. There is great business potential in solving control issues. Oscillating systems are forced to operate far from optimum, while consuming excess energy.

Integration between process and control

Have a well-controlled process with minimum variability.

Utilise existing devices

No need to change the existing field instrumentation.

Best control performance

Minimised variability opens the possibility of revealing new optimisation potential.

Remote Data Analysis

Connect with us, send data and simply get the result: we investigate your control problem remotely and deliver a free report about the potential control improvements.

GAP Analysis. The metrics show how far the current system is from desired, as well as the final achievable performance with the existing process and control devices.

Root Cause Analysis. Each root cause that acts as a barrier against the best performance is localised and explored.

Corrective Actions. The necessary and sufficient action list provides adequate engineering activities to bring technical and financial benefits.

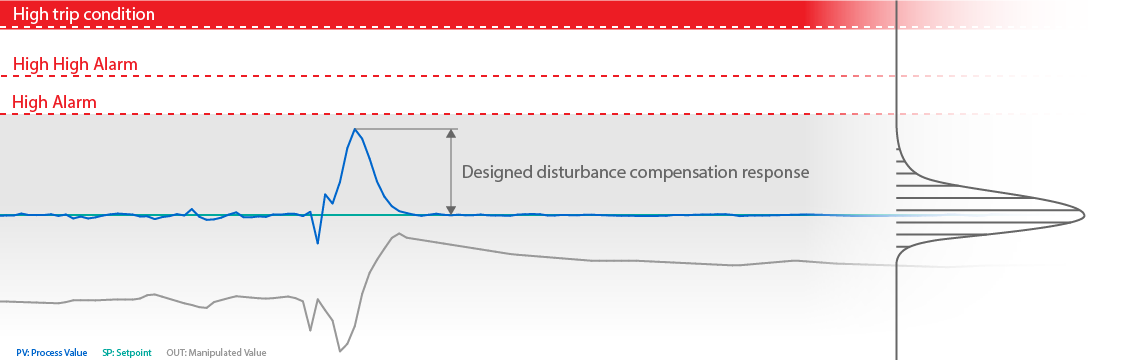

Designed Control Response

Closed control loop dynamics are redesigned for an entire process unit by adapting the control system parameters to achieve minimum overall variability. This design process makes it possible to justify the level of disturbance tolerance.

Benefits

Potential business benefits are assessed and delivered. Some benefit categories are industry and process specific. During the initial consultation process only the categories which deliver tangible benefits are assessed.

Operator load

The operators can turn their focus to the process rather than to its control.

Maintenance

Decreased variability results in slower asset deterioration.

Asset life

Less stress on process equipment increases its lifetime.

Alarm

Significantly reduced alarms.

Safety

Safer operation.

Typical data requirement

Data analysis usually requires the following data inputs. If you send us the design documentation we can prepare a Data Request Requirement for you.

A custom non-disclosure agreement is available on request.

|

|

Time series data |

|

|

Operator schematics |

|

|

Process control system configuration |

|

|

Piping and instrumentation diagram |